Flanges

A class 150 flanges can be created from various materials like stainless steel, carbon steel, mild steel, alloy steel, etc. and is resistant to abrasion & corrosion with high durability. Flanges such as American standard flanges, British standard flanges, German standard flanges, Indian Standard Flanges & Japanese Standard Flanges created using above mentioned materials have separate pressure ratings.

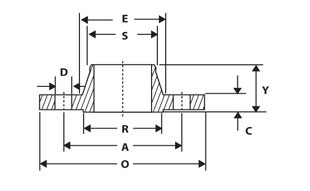

Welding neck flanges

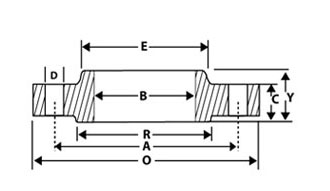

Slip on flanges

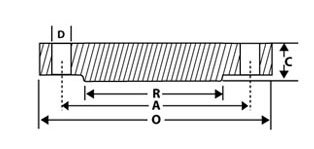

Blind flanges

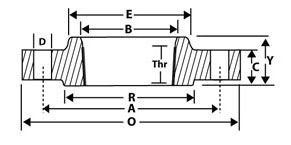

Threaded flanges

Lap joint flanges

Socket weld flanges

The pressure rating of flanges depends on various factors which we will look at in the following section.

Flanges are able to resist different pressure values at different & varied temperatures. With increase in temperature pressure rating of a flange decreases. Let us take an example to illustrate what happens; Class 150 flanges rates to about 270 PSIG (in ambient conditions), at 400 F a PSIG of 180, at 600 F a PSIG of 150 & 75 PSIG at 800 F. So it all depends on the fluid’s operating temperature.

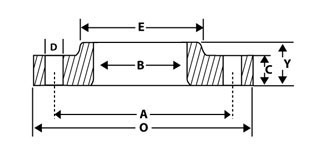

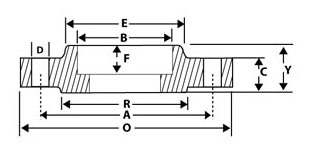

| DIMENSIONS OF CLASS 150 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel 'S' |

Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F 'R' |

Depth of Socket 'F' |

Length of Threading |

||||

| S/O & S/W 'Y' |

W/N 'Y' |

L/J 'Y' |

S/O & S/W 'B' |

L/J 'B' |

||||||||||||

| 1/2'' | 15 | 88.9 | 60.3 | 15.9 | 4 | 11.1 | 21.3 | 30.2 | 15.9 | 47.6 | 15.9 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

| 3/4'' | 20 | 98.4 | 69.8 | 15.9 | 4 | 12.7 | 26.7 | 38.1 | 15.9 | 52.4 | 15.9 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 107.9 | 79.4 | 15.9 | 4 | 14.3 | 33.5 | 49.2 | 17.5 | 55.6 | 17.5 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 ¼'' | 32 | 117.5 | 88.9 | 15.9 | 4 | 15.9 | 42.2 | 58.7 | 20.6 | 57.1 | 20.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 ½'' | 40 | 127.0 | 98.4 | 15.9 | 4 | 17.5 | 48.3 | 65.1 | 22.2 | 61.9 | 22.2 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 152.4 | 120.6 | 19.0 | 4 | 19.0 | 60.4 | 77.8 | 25.4 | 63.5 | 25.4 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 ½'' | 65 | 177.8 | 139.7 | 19.0 | 4 | 22.2 | 73.1 | 90.5 | 28.6 | 69.8 | 28.6 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 190.5 | 152.4 | 19.0 | 4 | 23.8 | 88.9 | 107.9 | 30.2 | 69.8 | 30.2 | 90.7 | 91.4 | 127.0 | 20.6 | 30.2 |

| 3 ½'' | 90 | 216.0 | 177.8 | 19.0 | 8 | 23.8 | 101.6 | 122.2 | 31.7 | 71.4 | 31.7 | 103.4 | 104.1 | 140.0 | 20.6 | 31.7 |

| 4'' | 100 | 228.6 | 190.5 | 19.0 | 8 | 23.8 | 114.3 | 134.9 | 33.3 | 76.2 | 33.3 | 116.1 | 116.8 | 157.2 | 23.8 | 33.3 |

| 5'' | 125 | 254.0 | 215.9 | 22.2 | 8 | 23.8 | 141.2 | 163.5 | 36.5 | 88.9 | 36.5 | 143.8 | 144.5 | 185.7 | 23.8 | 36.5 |

| 6'' | 150 | 279.4 | 241.3 | 22.2 | 8 | 25.4 | 168.4 | 192.1 | 39.7 | 88.9 | 39.7 | 170.7 | 171.4 | 215.9 | 27.0 | 39.7 |

| 8'' | 200 | 342.9 | 298.4 | 22.2 | 8 | 28.6 | 219.2 | 246.1 | 44.4 | 101.6 | 44.4 | 221.5 | 222.2 | 269.9 | 31.7 | 44.4 |

| 10'' | 250 | 406.4 | 361.9 | 25.4 | 12 | 30.2 | 273.0 | 304.8 | 49.2 | 101.6 | 49.2 | 276.3 | 277.4 | 323.8 | 33.3 | 49.2 |

| 12'' | 300 | 482.6 | 431.8 | 25.4 | 12 | 31.8 | 323.8 | 365.1 | 55.6 | 114.3 | 55.6 | 327.1 | 328.2 | 381.0 | 39.7 | 55.6 |

| 14'' | 350 | 533.4 | 476.2 | 28.6 | 12 | 34.9 | 355.6 | 400.0 | 57.1 | 127.0 | 79.4 | 359.1 | 360.2 | 412.7 | 41.3 | 57.1 |

| 16'' | 400 | 596.9 | 539.7 | 28.6 | 16 | 36.5 | 406.4 | 457.2 | 63.5 | 127.0 | 87.3 | 410.5 | 411.2 | 469.9 | 44.4 | 63.5 |

| 18'' | 450 | 635.0 | 577.8 | 31.7 | 16 | 39.7 | 457.2 | 504.8 | 68.3 | 139.7 | 96.8 | 461.8 | 462.3 | 533.4 | 49.2 | 68.3 |

| 20'' | 500 | 698.5 | 635.0 | 31.7 | 20 | 42.9 | 508.0 | 558.8 | 73.0 | 144.5 | 103.2 | 513.1 | 514.3 | 584.2 | 54.0 | 73.0 |

| 24'' | 600 | 812.8 | 749.3 | 34.9 | 20 | 47.6 | 609.6 | 663.6 | 82.5 | 152.4 | 111.1 | 615.9 | 615.9 | 692.1 | 63.5 | 82.5 |

Note : Thickness 'C' is inclusive of Raised Face Thickness of 1.65 MM. For Class 150