Flanges

A class 900 flanges can be created from various materials like stainless steel, carbon steel, mild steel, alloy steel, etc. and is resistant to abrasion & corrosion with high durability. Flanges such as American standard flanges, British standard flanges, German standard flanges, Indian Standard Flanges & Japanese Standard Flanges created using above mentioned materials have separate pressure ratings.

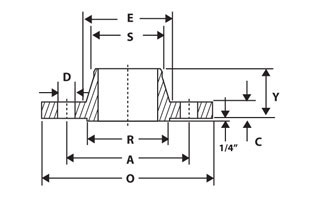

Welding neck flanges

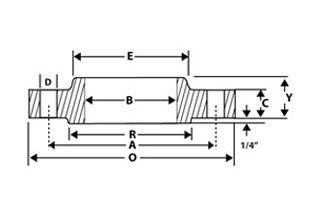

Slip on flanges

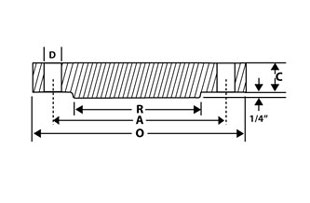

Blind flanges

Threaded flanges

Lap joint flanges

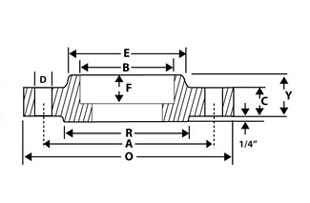

Socket weld flanges

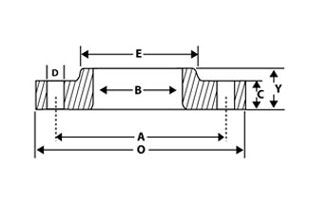

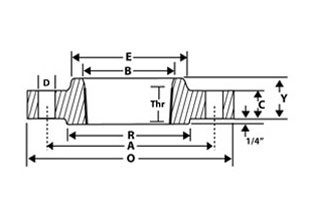

| DIMENSIONS OF CLASS 900 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel 'S' |

Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

|||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 120.6 | 82.5 | 22.2 | 4 | 22.2 | 21.3 | 38.1 | 31.7 | 60.3 | 31.7 | 22.3 | 22.9 | 34.9 | 9.5 | |

| 3/4'' | 20 | 130.2 | 88.9 | 22.2 | 4 | 25.4 | 26.7 | 44.4 | 34.9 | 69.8 | 34.9 | 27.7 | 28.2 | 42.9 | 11.1 | |

| 1'' | 25 | 149.2 | 101.6 | 25.4 | 4 | 28.6 | 33.5 | 52.4 | 41.3 | 73.0 | 41.3 | 34.5 | 35.0 | 50.8 | 12.7 | |

| 1 ¼'' | 32 | 158.7 | 111.1 | 25.4 | 4 | 28.6 | 42.2 | 63.5 | 41.3 | 73.0 | 41.3 | 43.2 | 43.7 | 63.5 | 14.3 | |

| 1 ½'' | 40 | 177.8 | 123.8 | 28.6 | 4 | 31.8 | 48.3 | 69.8 | 44.4 | 82.5 | 44.4 | 49.5 | 50.0 | 73.0 | 15.9 | |

| 2'' | 50 | 215.9 | 165.1 | 25.4 | 8 | 38.1 | 60.4 | 104.8 | 57.1 | 101.6 | 57.1 | 62.0 | 62.5 | 92.1 | 17.5 | |

| 2 ½'' | 65 | 244.5 | 190.5 | 28.6 | 8 | 41.3 | 73.1 | 123.8 | 63.5 | 104.8 | 63.5 | 74.7 | 75.4 | 104.8 | 19.0 | |

| 3'' | 80 | 241.3 | 190.5 | 25.4 | 8 | 38.1 | 88.9 | 127.0 | 53.9 | 101.6 | 53.9 | 90.7 | 91.4 | 127.0 | - | |

| 4'' | 100 | 292.1 | 234.9 | 31.7 | 8 | 44.4 | 114.3 | 158.7 | 69.8 | 114.3 | 69.8 | 116.1 | 116.8 | 157.2 | - | |

| 5'' | 125 | 349.2 | 279.4 | 35.0 | 8 | 50.8 | 141.2 | 190.5 | 79.3 | 127.0 | 79.3 | 143.8 | 144.5 | 185.7 | - | |

| 6'' | 150 | 381.0 | 317.5 | 31.7 | 12 | 55.6 | 168.4 | 234.9 | 85.8 | 139.7 | 85.8 | 170.7 | 171.4 | 215.9 | - | |

| 8'' | 200 | 469.9 | 393.7 | 38.1 | 12 | 63.5 | 219.2 | 298.4 | 101.6 | 162.0 | 114.3 | 221.5 | 222.2 | 269.9 | - | |

| 10'' | 250 | 546.1 | 469.9 | 38.1 | 16 | 69.8 | 273.0 | 368.3 | 107.9 | 184.1 | 127.0 | 276.3 | 277.4 | 323.8 | - | |

| 12'' | 300 | 609.6 | 533.4 | 38.1 | 20 | 79.4 | 323.8 | 419.1 | 117.4 | 200.0 | 142.7 | 327.1 | 328.2 | 381.0 | - | |

| 14'' | 350 | 641.3 | 558.8 | 41.3 | 20 | 85.7 | 355.6 | 450.8 | 130.2 | 212.7 | 155.6 | 359.1 | 360.2 | 412.7 | - | |

| 16'' | 400 | 704.8 | 615.9 | 44.4 | 20 | 88.9 | 406.4 | 508.0 | 133.3 | 215.9 | 165.9 | 410.5 | 411.2 | 469.9 | - | |

| 18'' | 450 | 787.4 | 685.8 | 50.8 | 20 | 101.6 | 457.2 | 565.1 | 152.4 | 228.6 | 190.5 | 461.8 | 462.3 | 533.4 | - | |

| 20'' | 500 | 857.2 | 749.3 | 54.0 | 20 | 107.9 | 508.0 | 622.3 | 158.7 | 247.6 | 209.5 | 513.1 | 514.3 | 584.2 | - | |

| 24'' | 600 | 1041.4 | 901.7 | 66.7 | 20 | 139.7 | 609.6 | 749.3 | 203.2 | 292.1 | 266.7 | 615.9 | 615.9 | 692.1 | - | |

Note : Thickness 'C' is exclusive of Raised Face Thickness of 6.25 MM. For Class 900